Waikato Centre for Advanced Materials and Manufacturing (WaiCAMM)

Our mission is to develop sustainable and functional materials to address societal needs using reliable and efficient manufacturing methods.

This interdisciplinary research centre encompasses a broad range of world-leading expertise in natural fibre and high performance composites, powder metallurgy and specialty alloys, functional materials, characterisation, through life inspections and failure prediction.

WaiCAMM is always open to establishing partnerships with industry and research organisations to strengthen the materials research capability in New Zealand. Organisations interested in establishing partnerships with WaiCAMM are invited to contact members of our team directly.

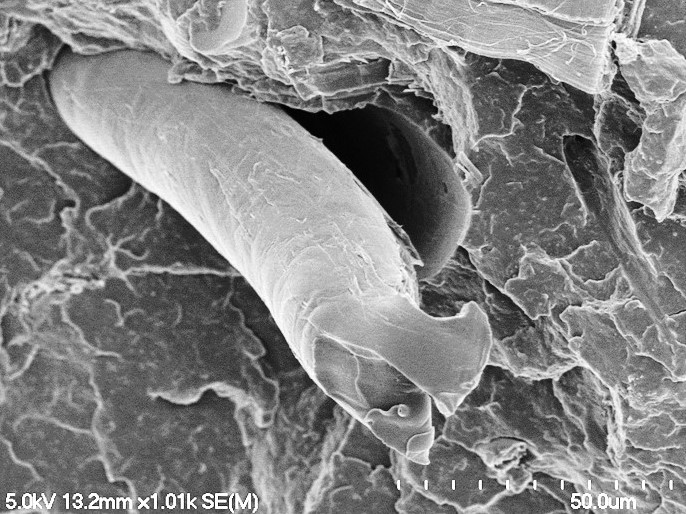

Polymers and composites research

Research is focussed on understanding the relationship between the behaviour of polymeric/composite materials and their structure, elucidating the mechanisms involved in their behaviour, thus supporting the ability to engineer behaviour in new materials and optimise them for a wide range of applications. Our specialist expertise includes:

- Natural fibre composites (including hemp, harakeke and wood)

- High performance composites

- 3D-> 4D printing

- Nanocellulose

- Self healing composites

- Fracture mechanics and failure prediction

- Protein derived polymers

- Magnetorheological materials

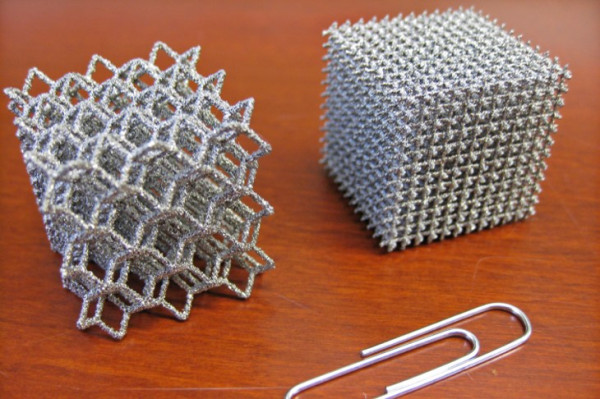

Metals and advanced alloys research

Our research is centred around the interdisciplinary field of physical metallurgy aiming to master processing-structure-properties relationships to develop futuristic advanced metallic materials and sustainable Industry 4.0 production ecosystems. Alloy customisation and process optimisation are keys for the establishment of environmentally friendly metamorphic manufacturing capabilities for high added-value on-demand products. Our specialist expertise includes:

- Powder metallurgy

- Advanced solidification

- Additive manufacturing (3D printing)

- Low cost high performance titanium alloys

- High entropy alloys

- Antibacterial biomedical alloys

- Architectured materials

- Advanced heat sink materials

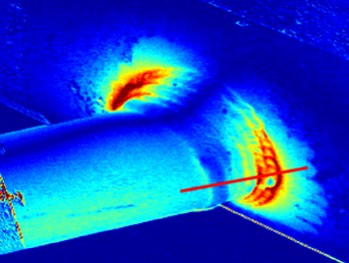

Inspection and characterisation research

Materials should be used in an appropriate way. Our focus is to ensure the materials used are able to be inspected to reveal important defects, understand the impact of those defects on the structure, and monitor progression of any damage caused by in-service loads. Our specialist expertise includes:

- Non-destructive evaluation

- Experimental mechanics and stress assessment

- Through life monitoring

- Fracture mechanics and failure prediction