Cold-formed Steel Structures Group

Our mission is to conduct world-leading industry-led research into the use of cold-formed steel in construction in Aotearoa.

The Cold-Formed Steel Structures Research Group at the University of Waikato comprises three full-time academics (Professor James Lim, Dr Krishanu Roy and Dr Arthur Zhiyuan Fang), 15 PhD students and 15 Master students. We welcome you to our webpage and hope we can welcome you to Aotearoa soon and interact with our group.

Please feel free to reach out to any of us if you have any questions:

We are not limited in our scope to building systems composed only of cold-formed steel, but are interested in solutions that use the appropriate building materials, whether it be for sustainability or affordability issues. Our research includes modern methods of construction, such as FRP or 3D printed concrete, with cold-formed steel used for the roof truss, cladding, lintels etc.

We would be very happy to receive applications for both PhD and ME on structural engineering as well on other topics of interest. View our step-by step guide to apply for our ME. Tuition fees are around $49k in total for this one-year 120 pt ME. Scholarships are available for ME applicants from India and China. Please find our scholarships available for students from other countries. We work closely with our ME students and help them find industry led research topics (if they wish), and jobs on completion. Read about our students.

About us

We use a combination of experimental field tests, smaller-scale laboratory tests, finite element analysis (ANSYS and ABAQUS), machine learning and optimisation to understand the structural behaviour, environmental / sustainability issues related to the use of cold-formed steel. We have a smart digital laboratory and are interested in Construction 4.0, VR/AR, BIM, as appropriate to our research and teaching of cold-formed steel construction.

Our group has recently moved to University of Waikato, having previously been based at University of Auckland, where we maintain a strong collaborative relationship. Here in New Zealand, we have attracted support from industry of more than $3 million dollars that supports post-docs, PhD students and experimental tests. We have published around 200 journal papers. We currently have around 15 PhD students. We have a structures laboratory located in Frankton, Hamilton. Our equipment includes compression and bending test rigs, wind box for roofing tests etc.

We are part of the QuakeCoRE and New Zealand Product Accelerator.

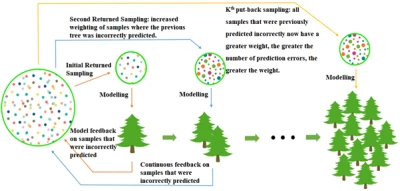

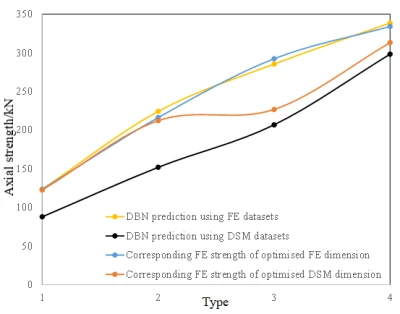

Machine Learning

We apply machine-learning techniques to to cold-formed steel structures through an integrated approach that includes extensive laboratory testing and finite element analysis. One of our early papers entitled "Deep learning-based procedure for structural design of cold-formed steel channel sections with edge-stiffened and un-stiffened holes under axial compression" is now one of the most highly cited papers in Thin-Walled Structures, and one of the earliest papers to apply machine-learning to cold-formed steel. To date we have published 7 papers on machine-learning in this and other journals. Our research is led by Dr Arthur Fang. Please feel free to contact arthur.fang@waikato.ac.nz if you have any interest in our research, or if you are interested in collaboration.

Currently, we are investigating the following areas:

Currently, we are investigating the following areas:

- Massive database for structural analysis system;

- Effective machine-learning tool for structural analysis;

- Intelligent building design;

- Artificial intelligence in sustainability.

Portal Frames

Our research comprises full-scale testing and finite element modeling to understand the behavior of portal frames. This includes framing and joints as well as the influence of stressed-skin diaphragm action.

Roofing

During strong wind occurrences, cold-formed steel (CFS) roof claddings are exposed to severe suction/uplift forces. In regions where the prevailing winds are strong, such as New Zealand. The turbulence of the wind flow around the building generates suction pressures, which vary both spatially and temporally. According to observations, the weakest link in the roofing system is the connection between the roof sheeting and the screw fasteners, which, if they break, may lead to progressive roof loss. High wind suction pressure fluctuations may cause static or fatigue pull-through failure of the roof sheeting at its screw fastener connections.

As a result, our team has done considerable research on full-scale tests and finite element modelling of roofing and cladding systems subjected to static and constant amplitude cyclic wind loading.

FRP wall panels

We have recently signed an MOU with Affordable Housing Ltd, a construction company and the developer and provider of SAIMU FRP structural wall panel building system in Hamilton, to improve further understanding and conduct ongoing research and development on the structural behavior of their innovative Fibre Reinforced Polymer (FRP) wall building systems, concerning structural strength, seismic behavior, durability and fire resistance for residential and commercial buildings in New Zealand and possibly countries in the pacific rim.

We have recently signed an MOU with Affordable Housing Ltd, a construction company and the developer and provider of SAIMU FRP structural wall panel building system in Hamilton, to improve further understanding and conduct ongoing research and development on the structural behavior of their innovative Fibre Reinforced Polymer (FRP) wall building systems, concerning structural strength, seismic behavior, durability and fire resistance for residential and commercial buildings in New Zealand and possibly countries in the pacific rim.

Fire

There is a lack of understanding on the behaviour of cold-formed steel structures subject to fire. For the case of single storey buildings, our team has led the experimental testing to collapse of two such buildings in collaboration with Professor Lau of Swinburne University.

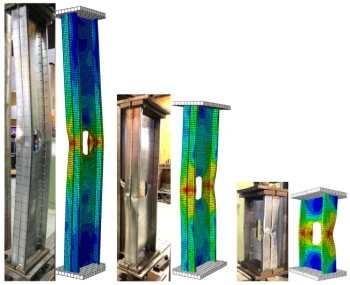

Beams and Columns with Openings

Openings for service integration are very important for cold-formed steel construction. There is often a lack of guidance in the codes and standards. Our team investigates using a combination of experimental testing and finite element modeling to understand the effect of openings. We have found that the used of edge stiffened openings can sometimes increase the strength beyond that of sections without openings e.g. in the case of web crippling.

Optimisation

At the request of industry, we have used optimisation techniques to investigate potential cost and material savings in steel framed buildings. These can be up to 30% for both tapered sections portal frames as well as cold-formed steel portal frames. We can optimise members as well eg channel sections under compression.

At the request of industry, we have used optimisation techniques to investigate potential cost and material savings in steel framed buildings. These can be up to 30% for both tapered sections portal frames as well as cold-formed steel portal frames. We can optimise members as well eg channel sections under compression.

Construction 4.0

Construction 4.0 can broadly be thought of as representing the digitization of the construction industry. Technologies like 3D scanning, robotics, 3D printing, machine learning and AI are part of this new digital revolution. Working with the product accelerator where we are the research lead, our team works on the use of scanning (with Waikato steel fabricators), Building Information Modelling (BIM) and VR/AR technology to help reduce the cost of housing.

Construction 4.0 can broadly be thought of as representing the digitization of the construction industry. Technologies like 3D scanning, robotics, 3D printing, machine learning and AI are part of this new digital revolution. Working with the product accelerator where we are the research lead, our team works on the use of scanning (with Waikato steel fabricators), Building Information Modelling (BIM) and VR/AR technology to help reduce the cost of housing.

Our team

Senior Lecturer

Professor

The Dr John Gallagher Chair in Engineering

Lecturer

Senior Lecturer

Our students

We would be very happy to receive applications for both PhD and ME on structural engineering as well other topics of interest. View our Step by Step Guide on ME Research Online Application.

Completed PhD Students

- Dr Boshan Chen

- Dr Milad Jabbari

- Dr Hafez Taheri

- Dr Milad Bahrebar

- Dr Maelle Van Thinen

- Dr Amir Shahmohamady

- Dr Krishanu Roy

- Dr James Maguire

- Dr Amirmohammad Yousefi

- Dr Kingsley Ukanwa

- Dr Andrzej Wrzesien

- Dr Migel Paya

- Dr Ying Lian

- Dr Ross McKinstray

- Dr Ross Johnston

- Dr Mahbubur Rahman

- Dr Duoc Phan

- Dr Asraf Uzzaman

- Dr Gordon Callaghan

- Dr Zhenghao Tang

- Dr Hooman Rezaeian

- Dr Zubin Karami